In the intricate realm of nutritional science, the synthesis of essential B vitamins represents a fascinating process that merges scientific ingenuity with natural compounds. B vitamins, a group of water-soluble micronutrients crucial for various physiological functions, are integral to our health and well-being. This comprehensive exploration delves into the intricate world of how B vitamins are made, unraveling the scientific processes, sources, and the technological advancements that enable the production of these vital nutrients.

Understanding the B Vitamin Family

The B Vitamin Spectrum:

Before delving into the manufacturing intricacies, it’s paramount to comprehend the diversity within the B vitamin family. This group comprises eight distinct members, each playing a unique role in cellular metabolism, energy production, and overall vitality. The B vitamins include B1 (thiamine), B2 (riboflavin), B3 (niacin), B5 (pantothenic acid), B6 (pyridoxine), B7 (biotin), B9 (folate), and B12 (cobalamin).

Water-Soluble Marvels:

B vitamins, unlike their fat-soluble counterparts, dissolve in water. This characteristic necessitates regular replenishment through diet or supplementation, as they are not stored in the body for extended periods. Their water solubility also influences the manufacturing processes employed to ensure their stability and bioavailability.

Natural vs. Synthetic B Vitamins

Sourcing B Vitamins Naturally:

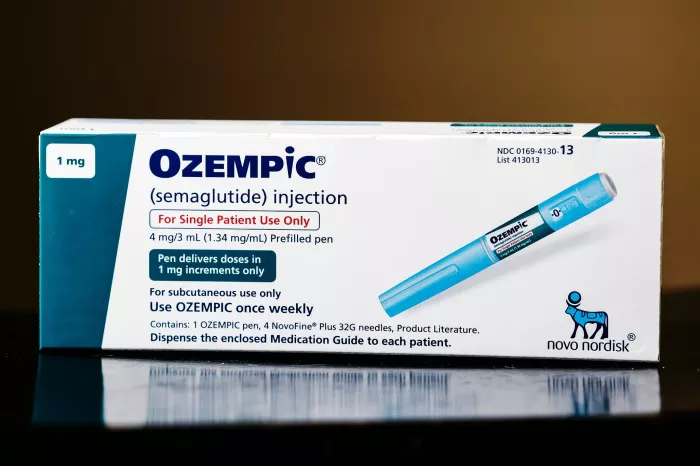

Historically, B vitamins were primarily sourced from natural food derivatives. Yeast, liver, whole grains, and leafy greens served as rich reservoirs of these essential nutrients. However, advancements in manufacturing technology have introduced synthetic alternatives, raising questions about the comparative efficacy and bioavailability of natural versus synthetic B vitamins.

Natural Complexity vs. Synthetic Precision:

Natural sources of B vitamins encompass a complex matrix of compounds, cofactors, and phytonutrients that contribute to their bioavailability. Synthetic B vitamins, on the other hand, offer precision and consistency in dosage but lack the inherent complexities of their natural counterparts. The debate surrounding natural versus synthetic B vitamins underscores the evolving landscape of nutritional supplementation.

Manufacturing B1 (Thiamine) and B2 (Riboflavin)

B1 (Thiamine) Synthesis:

Thiamine, also known as B1, is essential for energy metabolism and nerve function. The synthesis of B1 involves the condensation of pyrimidine and thiazole moieties, resulting in the formation of thiamine. Fermentation processes using bacteria, yeast, or fungi serve as the foundation for B1 production.

B2 (Riboflavin) Production:

Riboflavin, or B2, plays a key role in energy production and antioxidant processes. Commercially, B2 is predominantly produced through microbial fermentation. Bacteria such as Bacillus subtilis or Ashbya gossypii are employed to ferment raw materials, yielding riboflavin as a byproduct. Downstream processing isolates and purifies the synthesized B2.

B3 (Niacin) and B5 (Pantothenic Acid)

Niacin (B3) Synthesis:

Niacin, a pivotal player in energy metabolism, exists in two forms: nicotinic acid and nicotinamide. Industrial production of niacin often involves the hydrolysis of niacinamide from precursors like 3-cyanopyridine. This precursor undergoes complex chemical transformations, resulting in the synthesis of niacin.

Pantothenic Acid (B5) Biosynthesis:

Pantothenic acid, crucial for the synthesis of coenzyme A involved in energy metabolism, is synthesized through a multi-step process. The precursor beta-alanine undergoes condensation with pantoic acid, leading to the formation of pantothenic acid. Microbial fermentation, particularly using bacteria like Bacillus subtilis, facilitates B5 production.

B6 (Pyridoxine) and B7 (Biotin)

B6 (Pyridoxine) Production:

Pyridoxine, integral to amino acid metabolism, is synthesized through microbial fermentation. Bacterial strains like Escherichia coli or Bacillus subtilis are manipulated to express enzymes involved in pyridoxine biosynthesis. The fermentation process yields pyridoxine, which is subsequently extracted and purified.

Biotin (B7) Synthesis:

Biotin, a coenzyme essential for various metabolic processes, is often synthesized through microbial fermentation. Bacteria such as Escherichia coli are engineered to produce biotin efficiently. After fermentation, the biotin is separated and purified to create the final product.

Folate (B9) and Cobalamin (B12)

Folate (B9) Manufacturing:

Folate, vital for DNA synthesis and cell division, undergoes a complex manufacturing process. Initially synthesized as dihydrofolic acid, it undergoes multiple enzymatic transformations to yield the active form, methyltetrahydrofolate. The fermentation process, often involving yeast or bacteria, serves as the foundation for folate production.

Cobalamin (B12) Synthesis:

Cobalamin, the largest and most complex B vitamin, involves a intricate process. Bacterial fermentation using strains like Propionibacterium freudenreichii is a common method. These bacteria naturally produce B12 during their metabolic processes. Downstream processing involves purification and isolation to obtain the final cobalamin product.

Quality Control in B Vitamin Manufacturing

Purity and Potency Standards:

Maintaining stringent quality control standards is paramount in B vitamin manufacturing. The purity and potency of the synthesized vitamins are rigorously tested to ensure they meet regulatory requirements. Advanced analytical techniques, such as high-performance liquid chromatography (HPLC), play a crucial role in quality assurance.

Adherence to Good Manufacturing Practices (GMP):

B vitamin manufacturers adhere to Good Manufacturing Practices (GMP) to guarantee the safety, efficacy, and consistency of their products. GMP encompasses rigorous processes, documentation, and quality assurance measures throughout the entire manufacturing journey.

Third-Party Certification:

Some manufacturers opt for third-party certification, adding an additional layer of validation. Certifications from reputable organizations affirm the adherence to quality standards and provide consumers with confidence in the product’s authenticity.

The Future of B Vitamin Production

Biotechnological Advancements:

The future of B vitamin production holds promises of biotechnological advancements. Enhanced microbial strains, genetic engineering, and fermentation optimization are areas of exploration to improve efficiency and sustainability in the synthesis of B vitamins.

Sustainability in Sourcing:

As sustainability gains prominence, the sourcing of raw materials for B vitamin production is undergoing scrutiny. Exploring eco-friendly sources and adopting sustainable practices in manufacturing contribute to a holistic approach in the production of these essential nutrients.

Consumer Education and Transparency:

The future landscape involves heightened consumer education and transparency. Empowering consumers with knowledge about the origin, production processes, and efficacy of B vitamins fosters an informed approach to nutritional supplementation.

Conclusion

In conclusion, the synthesis of B vitamins is a testament to the intersection of scientific innovation, microbial mastery, and the quest for nutritional well-being. From the microbial fermentation processes that yield B1, B2, B3, B5, B6, and B7 to the intricate biosynthesis of B9 and the complexity of B12 production, each B vitamin has a unique journey from raw materials to the final supplement. The ongoing discourse on natural versus synthetic sources and the advancements in manufacturing underscore the dynamic landscape of B vitamin production. As technology evolves and sustainability takes center stage, the alchemy behind B vitamins continues to unravel, offering a glimpse into the future of nutritional science.

[inline_related_posts title=”You Might Be Interested In” title_align=”left” style=”list” number=”6″ align=”none” ids=”3600,3598,3432″ by=”categories” orderby=”rand” order=”DESC” hide_thumb=”no” thumb_right=”no” views=”no” date=”yes” grid_columns=”2″ post_type=”” tax=””]